Materials Test Lab Solutions: Crafting Certainty in Every Evaluation

Wiki Article

From Idea to Reality: The Significance of Products Testing in Item Advancement

Materials testing is the methodical exam and evaluation of the residential or commercial properties and behavior of numerous materials made use of in item development. By subjecting products to strenuous testing, item designers can make the most of item top quality, integrity, and inevitably, consumer complete satisfaction. This short article explores the importance of products screening in item development and highlights its value in turning cutting-edge concepts right into concrete, successful products.Defining Product Needs

To specify material requirements properly, extensive research and analysis are needed. The item advancement group need to consider factors such as mechanical properties, chemical sturdiness, compatibility, and cost-effectiveness. They need to additionally consider any kind of regulatory or safety and security requirements that the item needs to meet.

One of the crucial objectives in specifying material needs is to identify materials that can hold up against the anticipated stresses and strains the item will certainly experience throughout its lifecycle. This consists of considering elements such as temperature fluctuations, direct exposure to wetness or chemicals, and mechanical pressures. By choosing materials that can withstand these conditions, the product's efficiency and long life can be maximized.

Additionally, defining product demands additionally includes taking into consideration the aesthetic and responsive qualities of the materials. The visual allure, appearance, and feel of the item play a significant role in its bankability and individual experience.

Conducting Toughness and Sturdiness Checking

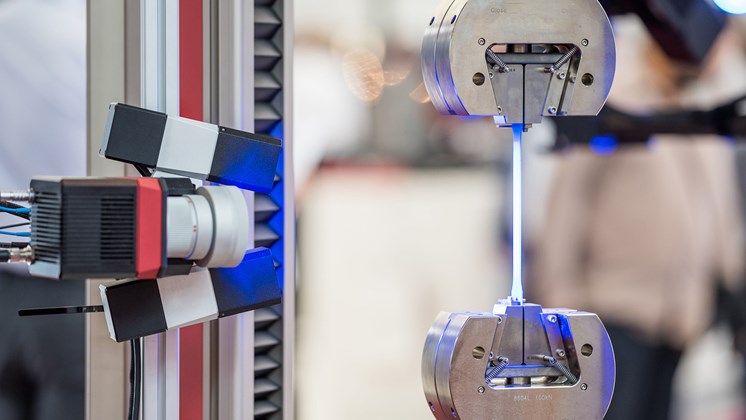

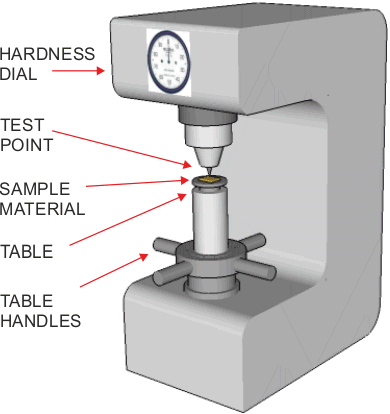

To guarantee the reliability and long life of a product, performing toughness and sturdiness testing is essential in the product development procedure. This sort of screening permits producers to understand exactly how a product will certainly do under various conditions and stress and anxiety degrees, aiding them make educated choices about design alterations and material selections.Stamina testing includes subjecting a product to regulated pressures to establish its capability to stand up to tons and stress. This can be done through tests such as stress, compression, flexing, and torsion examinations. By gauging the product's feedback to these forces, engineers can analyze its architectural honesty and determine any weaknesses or potential failing factors.

Reviewing Chemical Make-up and Compatibility

Chemical make-up and compatibility examination is an essential action in the product development procedure as it allows makers to assess the viability of products for their designated applications. Understanding the chemical make-up of a product is vital to ensure that it fulfills the needed requirements for efficiency, performance, and safety and security.Throughout the analysis process, manufacturers examine the chemical composition of materials to establish their residential or commercial properties, such as stamina, resistance, and sturdiness to rust. This info assists in choosing one of the most proper products for specific applications, as different products might have differing chemical make-ups that impact their performance.

Compatibility evaluation is just as vital, as it makes certain that the products made use of in an item are compatible with each various other and with any type of various other substances they might enter into contact with. Incompatibility can bring about chemical responses, degradation, or perhaps failing of the product.

To examine chemical compatibility, suppliers conduct tests to analyze and mimic real-world conditions exactly how various materials interact. These examinations may consist of direct exposure to numerous temperatures, pressures, and chemicals. The outcomes of these examinations assist suppliers determine any type of prospective problems and make educated decisions concerning material option and design alterations.

Assessing Safety And Security and Performance Criteria

Producers must thoroughly examine safety and security and efficiency requirements to ensure the top quality and integrity of their items. The evaluation of safety criteria includes evaluating the item's capability to run securely and without positioning any kind of dangers to consumers. This consists of assessing whether the product fulfills industry-specific safety and security laws and criteria, along with carrying out examinations to determine prospective threats and threats. Efficiency criteria, on the various other hand, emphasis redirected here on assessing the item's capability to fulfill details efficiency requirements and specs. This includes testing the item under various conditions to make sure that it executes as anticipated and meets the requirements of the desired users. By examining safety and security and efficiency requirements, producers can recognize any possible issues or imperfections in their items and take the essential actions to address them. This not just helps in ensuring the safety and security of consumers yet also enhances the general top quality and integrity of the products. It is crucial for manufacturers to invest in complete screening and evaluation procedures to construct trust with their customers and keep their track record in the marketplace.

Taking Full Advantage Of Item Top Quality and Reliability

By ensuring the thorough assessment of security and efficiency requirements, producers can successfully take full advantage of the quality and reliability of their items. Making the most of product high quality and integrity is vital for businesses to acquire an one-upmanship and preserve client complete satisfaction - materials test lab. To accomplish this, producers must employ strenuous screening methods throughout the product growth procedureOne crucial element of maximizing product quality and dependability is performing thorough materials testing. This involves evaluating the homes and attributes of the materials used in the manufacturing of the item. By examining the products for aspects such as resistance, toughness, and resilience to ecological conditions, makers can recognize possible weak points and make required renovations to boost the overall quality and dependability of the product.

Additionally, producers must additionally think about utilizing advanced screening methods, such as non-destructive testing (NDT) NDT allows useful reference for the examination of a product's stability without causing damages, ensuring that the top quality and reliability of the item are not compromised during the screening procedure.

Furthermore, makers need to continuously examine the performance and keep an eye on of their items in real-world problems. This can be done with area testing and celebration responses from consumers. By collecting and assessing data on product performance, manufacturers can determine locations for enhancement and make essential changes to enhance the high quality and reliability of their items.

Conclusion

In final thought, materials testing plays an essential role in product development by ensuring that the products used satisfy the needed requirements for toughness, durability, chemical make-up, performance, security, and compatibility standards. By performing detailed testing, suppliers can make best use of the top quality and integrity of their products - materials test lab. It is necessary to prioritize materials testing throughout the growth procedure to make sure the successful awareness of concepts right into concrete productsProducts testing is the organized assessment and evaluation of the properties and behavior of various products utilized in item advancement. By subjecting products to extensive testing, product developers can take full advantage of item high click to find out more quality, integrity, and ultimately, client fulfillment.One of the crucial objectives in specifying product demands is to recognize materials that can endure the anticipated stress and anxieties and pressures the product will experience throughout its lifecycle. By accumulating and analyzing data on item efficiency, makers can recognize areas for enhancement and make necessary adjustments to improve the quality and reliability of their products.

In verdict, products screening plays a crucial role in product growth by making sure that the materials made use of fulfill the necessary demands for stamina, resilience, chemical make-up, performance, safety and security, and compatibility standards.

Report this wiki page